How are robots used in the car industryThe automotive industry’s demand for industrial robots is forecast to treble in the subsequent seven years, according to a new report. An additional aspect that is holding back adoption of robotic systems is a lack of available abilities. Sadly, this is a wider difficulty that affects a lot more than just the robotics sector, but locating technicians, engineers and managers who have the skills to conceptualise, specify, buy, install and handle robotic systems is frequently off-placing for organisations. As these engineers are scarce, they are in higher demand and can be very mobile. The predicament is complicated additional by a scarcity of coaching and education courses obtainable to create or re-train engineers. With such a lack of skilled engineers, it is hardly surprising that there is not the capacity or understanding either within organisations or in the supply chain to develop, install and manage robotics systems appropriately and effectively.

Virtually half of the world’s automation technologies is getting utilized by the automotive business. With an enhance in customer demand, the automation technology has expanded its scope and applicability. The automated production processes support manufacturers boost their profit possible and meet market expectations. Robotics enhance the all round efficiency of a manufacturing method by making effective indicates of completing production tasks. As opposed to humans, robots do not get tired and can operate for days even though meeting the good quality and quantity requirements simultaneously. Modern industrial robots have the capacity to adapt and take crucial decisions during operations.

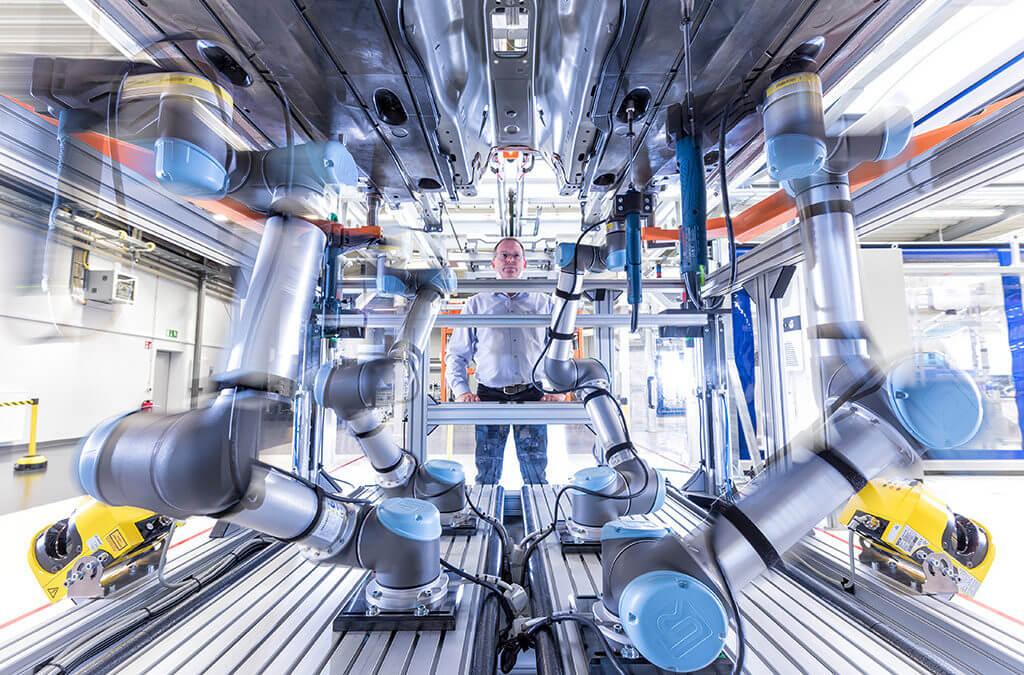

The man-machine partnership will assume a crucial part in advancing intelligent production visions (Industry 4.). Here, user-friendly robots are opening up opportunities for automation in differing sectors. The future possible of these robots is emphasized by comparing robotic density across different sectors. For instance, the Japanese automotive industry has a record 1,520 industrial robots per ten,000 personnel. The equivalent quantity in all other industries is just 214 units. Germany and the USA show a comparable picture.

Automotive Automation & Roboticshow are robots used in the automotive industry

how are robots used in the car industryThe automotive industry’s demand for industrial robots is forecast to treble in the subsequent seven years, according to a new report. 26. This segment largely involves spot welding and arc welding which is primarily utilized by the automotive business. Spot welding is still far more po pular than robotic arc welding but not for long; as arc welding is becoming quite well-known in the me tal business. Far more small operate shop are starting to introduce welding robot into their pr oduction. In truth, with the value of robot going down and the different tool now offered on the m arket, it is now simpler to automate a welding process.

Let’s begin by searching at possibly the most popular luxury automobile brand: Ferrari. Known for their ultra-higher performance, top end elements and luxurious amenities, Ferrari is the platonic perfect of high-end sports vehicles. They are remarkable pieces of automotive technologies and their brand says it all: they ARE the Ferrari of Ferrari afterall. They began as a company developing high efficiency race cars and that is the niche they have served given that. They utilize the highest level of automotive technology, are built in small quantities with exacting standards and wrapped in an aesthetically pleasing package — at a high value point, of course. They would not have it any other way.

Car manufacturing robots give automotive firms a competitive benefit. They improve good quality and minimize warranty costs enhance capacity and relieve bottlenecks and protect workers from dirty, difficult and harmful jobs. Vehicle assembly plants use robots exclusively for spot welding and painting, but there are several other possibilities to use robots throughout the supply chain. OEMs, Tier 1s and other component producers all stand to obtain from using robotics in the automobile business.

Robots Have On The UK Automotive Market?how are robots used in the car industry

how are robots used in the car industryThe automotive industry’s demand for industrial robots is forecast to treble in the next seven years, according to a new report. Robot (2D and 3D) vision requires employing a combination of camera hardware and personal computer algorithms to allow robots to method visual data from the globe. It is utilised in a quantity of ways throughout the automotive provide chain. Its main applications are making certain the good quality of the finish solution and enabling robots to be flexible and adaptive in portion-selecting and logistics.

Tesla, a U.S. electric auto manufacturer, relies heavily on automation. Elon Musk, the company’s CEO, announced plans to enhance the company’s production capacity fivefold to 500,000 automobiles a year by 2018. Several in the business are skeptical he can pull this off, but if he does, it will be virtually completely due to a manufacturing model driven by robots.

Getting the sunrise sector for the ‘Make in India’ campaign and 1 of the crucial sectors contributing towards the GDP of the nation, the automotive manufacturing segment has been producing speedy strides in the industrial automation domain emerging as a role model for the other industries by showcasing how automation need to be utilised to scale up the worth chain and obtain zero-defects manufacturing.

The History Of Robotics In The Automotive Businesshow are robots used in the car industry

how are robots used in the automotive industryThe automotive industry’s demand for industrial robots is forecast to treble in the subsequent seven years, according to a new report. The U.S. economic recovery also masks the urgency of the automation question. Auto sales hit an all-time high of 17.55 million units final year. U.S. auto plants are running full-tilt and employment in the market has ticked up as nicely. Nick Kottalis, a trade union leader at a Ford truck factory, thinks the company has weathered the crisis and is now escalating employment thanks to the difficult operate of folks, not robots. “Folks on production lines perform so hard – ten to 11 hours each single day – to make their living,” Kottalis stated with pride.

Despite a widespread belief that automation eliminates jobs in the automotive industry, the opposite is taking place in Germany as effectively as other nations. In the course of the 2010-2015 period, the number of staff in the German automotive business expanded by 14% to attain 710,000 workers in the latter year. But there is a cost. For each added robot introduced per thousand workers, five or six men and women shed their jobs, according to a paper presented in late March by Massachusetts Institute of Technology professor Daron Acemoglu and his colleagues. The paper brought on ripples in market.

Though several have worried that automatic production is taking away employment, these robots have protected workers from hazardous fumes, hot moldings and other harmful conditions, and have eliminated human error resulting from tedious operations and negligence brought on by tiredness at the finish-of-shifts. The ever-escalating manufacturing speed and precision brought by advancements of robotic technology have provided automakers an crucial competitive edge in creating premier top quality automotives. Security, high quality, and capability are the major reasons for adopting robotic technology.